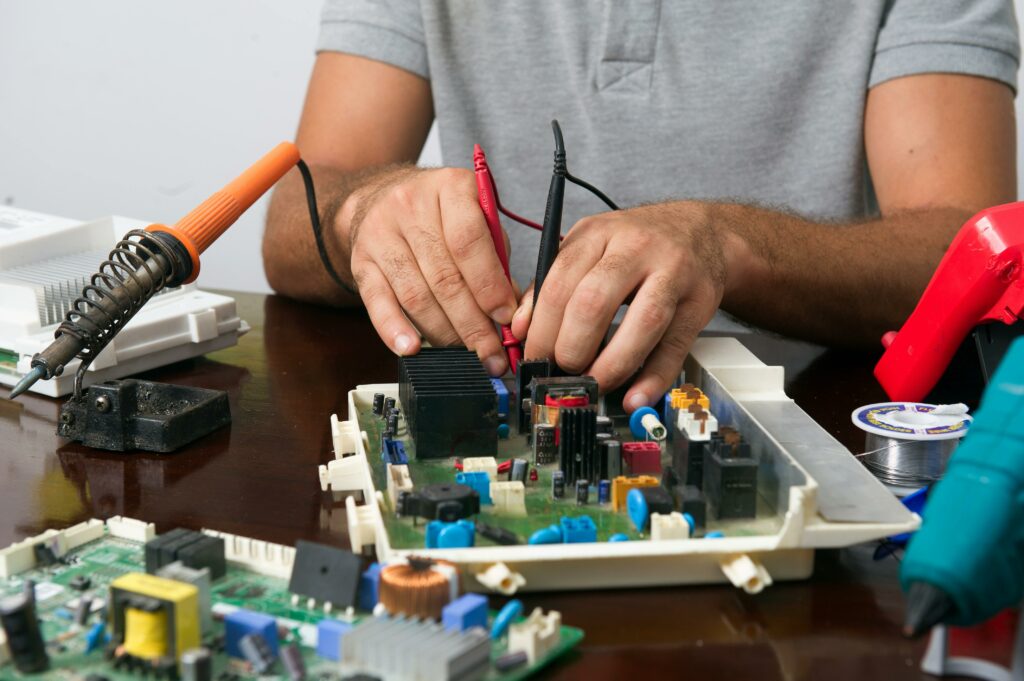

These days, we rely on electrical products at all times. This means that the reliability of these products is paramount, from the smartphones we use to the critical components in industrial machinery. Ensuring these items can withstand the rigours of their environment is a must to guarantee safety, performance, and customer satisfaction. This is where environmental testing comes into play and is a critical step for manufacturers of electrical goods in all sectors.

Product Safety & Reliability

Thorough testing under simulated real-world conditions can help ensure these products will perform as expected under things like extreme temperatures, vibration, and humidity, which is vital when lives are on the line. Sophisticated test equipment used in these processes, such as environmental chambers and vibration tables, provides the precise control and data needed to validate the reliability of these products. This allows manufacturers to release products that will not endanger the public – this is particularly important in industries where product failure can have serious consequences, such as aviation and healthcare.

Compliance with Industry Standards & Regulations

Many industries have specific environmental testing requirements that products must meet in order to be certified or approved. Testing, therefore, ensures products meet these requirements and allows manufacturers to market their products confidently. This can also help to build trust with consumers, which is key to success.

Optimise Energy Efficiency & Reduce Waste

Testing can help identify inefficiencies in systems and address these, which can help to reduce energy consumptionand lower carbon emissions – something every business is looking to do in 2025. From this, you can target issues driving resource consumption and emissions early, enabling better accountability and contributing to a more sustainable future while lowering energy bills (a concern for many).

Identify Design Flaws & Areas for Improvement

Environmental testing can reveal weaknesses in the design of certain products or flaws in manufacturing that render the product ineffective. From this, products can be improved, leading to a more robust and reliable final product. This will improve customer satisfaction levels and help manufacturers achieve higher levels of success.

As you can see, the importance of environmental testing cannot be overstated. The world runs on electrical products and many of these are used daily and in situations where performance is critical to safety, so it is vital that rigorous environmental testing is performed to ensure that they will perform as designed and ensure customer satisfaction, whether this is testing a smartphone or a component in an industrial system.