Can Vertical Farming Help Feed The Planet?

In an unassuming Scottish warehouse, hundreds of thousands of plants are enjoying a blue sunset. Tomorrow they’ll experience a blue sunrise as the next day of their perfect summer continues, and on for 365 days a year.

A light “wind” may remove some moisture from the air so crops don’t drown – this is weather in a box, calibrated with care, without a clod of earth in sight. For some 20 days plants grown from seed will be nurtured, fed and watered and lit with a perfect cocktail of nutrients, given just the right hue from thousands of LEDs to photosynthesise until they’re perfect for supermarket shelves and the finest restaurants.

Here at Invergowrie, to the west of Dundee, is the cutting edge of vertical farming – where plant scientists, engineers and soil and crop experts are putting heads together to develop the cleanest and most efficient methods of growing crops. This includes the technology to avoid wasting a drop of water or a ray of light – which is tuned and optimised for photosynthesis. About half a million plants are grown at any one time in towers stacked with trays of precision grown plants, shielded from the pests of the outside world.

“You can grow as many crops in a 12-metre tower in a year as you can in a hectare of land in the summer,” says Andrew Lloyd, Chief Operating Officer at Scottish agritech business Intelligent Growth Solutions (IGS). “We need to change the way we grow and consume food – we simply don’t have enough land, water or soil to carry on as we have.”

IGS opened its Crop Research Centre at the James Hutton Institute in 2018 to develop vertical farming technology. Each of IGS’s internet-connected units uses up to 50% less power and 80% less labour than greenhouse growing and 96% less water than traditional agriculture. Each tower has a footprint of just 42 square metres and reach from six to 12 metres.

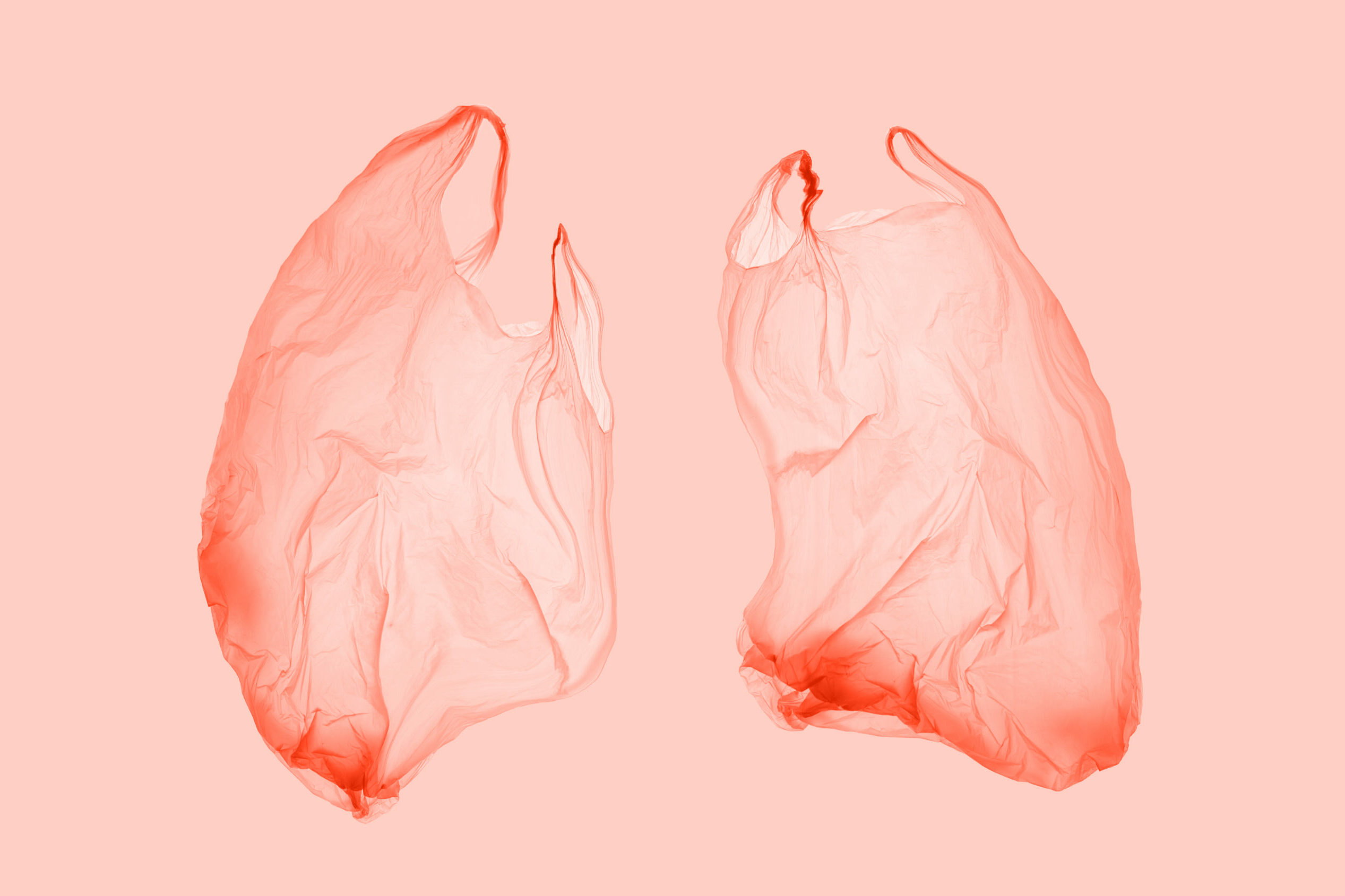

Vertical farming – a way of growing plants in a giant multi-storey potting shed, requiring less space and no pesticides – is a small piece of the puzzle of how the planet will feed nearly 10 billion people by the middle of this century. It allows growers precise, connected control over the environment, the weather, humidity and temperature, meaning they could grow locally, even in supermarket distribution centres, all year round.

By 2025, analysts estimate vertical farming will grow by 21%. Brexit and the pandemic have made us more aware of the fragility of food chains. A hotter world means it’s more urgent than ever to cut emissions from food miles, even in the middle of cities, where 70% of the population will live by 2050. Plants on tap could slash logistics and times from field to fork, and cut waste. Much fresh food travels more than a thousand miles or never makes it to the plate due to harsh weather, pests or disease – an estimated third of all food is wasted, with most wastage among fruit and vegetables.

Because plants grown this way don’t need to be washed, this doubles their shelf life. In 2019, UK online supermarket Ocado spent £17 million on vertical farming, investing in Scunthorpe-based Jones Food Company, Europe’s largest vertical farm, with the ultimate aim of delivering food within an hour of picking. Jones boasts the equivalent of 26 tennis courts of growing space and 12km of LED lights.

As future cities swell and space is tight, local vertical farms make perfect sense: a ready supply of just-in-time fresh produce. A handful of German supermarkets are already selling ‘locally’ grown greens within onsite vertical farms. Disused warehouses and industrial buildings could eventually house growing towers, and Lloyd expects they will spring up in supermarket distribution centres as early as next year. Highly urban Singapore already uses vertical farms to grow its greens.

"You can grow as many crops in a 12-metre tower in a year as you can in a hectare of land in the summer."

Plants are fed hydroponically, with nutrient-laden water delivered straight to their roots. Some vertical farms now use a nutrient packed mist, which means not a drop is wasted in closed loop systems

There is interest in IGS’s technology around the world: in North America, where efficient indoor farming makes economic sense; the Middle East, where arable land and water are in short supply; in East Asia with its densely populated cities. Coriander, spinach, kale and other brassicas and soft fruits make up some of the 150 plants under IGS’s artificial lights, and the company plans to showcase its farming technology at the UN climate conference COP26 in Glasgow this November. Chillis, baby beets and early stage tomatoes are some crops under investigation, and a major trial in seed potatoes is underway. Leafy greens are simplest to grow in towers – if plants need pollinating, some indoor growers release bees to do the job, while IGS might send short bursts of air to create a pollen cloud or deploy brushes. Automatic feedback systems enabled by intelligent sensors could boost plant yields and remove the need for human inspection.

Indoor farming won’t replace fields of corn, which are too heavy to grow indoors, or provide the wheat, maize and rice to stave off world hunger, but the crops emerging are now competitively priced.

But the hype around their potential – they’ve been around in earnest for more than a decade – hasn’t helped the sector, says Lloyd. “The industry needs to grow up – it’s been guilty of making some outrageous claims that are not backed by science or hard evidence,” he says. “And that undermines the credibility of the industry as a whole.”

More optimistic claims are that indoor farms recycle 100% of their water. “But that can’t possibly be true,” says Lloyd, “Because healthy plants heading for sale will contain some of that water.” And water will be precious in a warming world. While a kilo of lettuce grown in a field requires some 250 litres or 25 litres in a greenhouse, in a vertical farm this falls to just one litre.

Energy use is a thorny issue for vertical farms as LED lights typically use hefty amounts, and early incarnations have been wasteful. A nine-metre tower at IGS has some 124,000 LEDs and typically consumes 50kW. Ignoring construction and materials, towers can be carbon neutral if powered solely by renewable energy. But hooking them up directly to wind or solar plants is complex – farms need power even when the wind doesn’t blow and the sun isn’t shining. “It’s not an easy problem to solve but it’s an important one to solve,” says Lloyd.

When IGS has optimised lighting to use a minimum amount of energy. Light is tailored for individual crops and IGS produces a carefully calibrated ‘recipe’ of nutrients and lighting for each plant. Basil for instance, which accounts for 40% of the world’s herb production, likes blue, red and far-red parts of the spectrum. Plants need ultraviolet light to photosynthesise, a spell of infrared can boost leaves, while green light can help to increase yields – but no more than is necessary.

“Any time you see white light in vertical farms, you know energy is being wasted,” says Lloyd. “These won’t replace agriculture, they’ll supplement it, and they must work harder not to waste energy.”

Nor should you see individuals wandering around among the plants, he says; indoor cultivation means crops can be grown completely free of any pesticides, whereas the more people on site, the greater the risk they’ll bring in disease and pests. Processes at IGS are highly automated and mechanised; so much so that a single operator can control tens of thousands of plants remotely. Each growing tower is protected by an entry system with an airlock.

Calculating the carbon footprint of food is notoriously complex. ‘Home-grown’ British strawberries, sold in supermarkets and laybys in the UK, may have started life as a baby plant in Spain, although they may have been pollinated by British bees. “That’s the dirty little secret of some British-grown strawberries,” says Lloyd. But bananas which ripen as they ship make more sense than frozen produce flown around the world. “A general truism is that if you grow food to the same quality in the field outdoors, then go right ahead – that’s the most environmentally sustainable method. But you may only be able to grow those in June or July,” says Lloyd. “And the alternative is to import them from South America or South Africa. Whereas in Scotland we can replicate summer all year round.”

And although daylight comes for free in greenhouses, plants still need supplementary lighting and heat year round, and this often comes in the form of old and inefficient fluorescent lighting. Greenhouse plants need more watering than their cousins in vertical farms where yields are up to three times that of glasshouses, says IGS.

But will the public find the artifice of vertical farming unpalatable? That’s too early to say, says Lloyd. “Perhaps the only proxy we’ve got for this is organic,” he says. “It’s a question of what percentage of people will pay a premium for something which looks good, tastes great and is nutritious and genuinely additive free.”

While produce from indoor farms have been awarded organic status in the US, vertically farmed produce – although free of pesticides, insecticides and fungicides – can’t be classified in the UK, because of the UK’s Soil Association’s requirement that plants must be grown in organic soil. Although far from diesel powered tractors, plants in vertical farms are grown in substrates such as rock wool or coconut husk. In the future, growers might fortify plants with minerals such as selenium or zinc, Lloyd suggests. “The background science and the ability of the IGS Growth Tower to include the mineral or element enrichment in the nutrient IX is well proven.”

In its Future of Food report, the National Farmers Union acknowledged the contribution of vertical farms, but many consumers consider them ‘unnatural’. But nor are fields of cultivated single crops ‘natural’, say supporters. Anyone yearning for dirt under their fingernails and the green sunny fields of traditional farming should be aware of the march of progress – with innovations such as robotic fruit pickers, autonomous crop care, precision agriculture and advances in biotechnology on the horizon. “Our technology helps enable a greener future,” says Lloyd.